|

|

The

B oatA nchorM anualA rchivePath: /hallicra/r45arr7/r45mods/ |

This is the BAMA archive. These manuals are available for download and free of charge. Do not be tricked into paying for a manual that is available here for free.

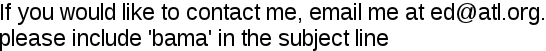

I am now accepting new manuals for inclusion in this archive. Contact and submission information below

Updates

-

2024-05-31

- Well, Google's 'advertising optimization' has now become so distracting as to trick people into visiting other sites. So I have removed advertising until I can find a better solution. One option may be sponsorship, anyone interested?

-

2026-01-26

- 383 new manuals added in abbott, ael, alinco, altair, amperex, associated_research, astatic, atlas, avo, awa, beitman, bitsavers, breting, bruel_kjaer, collins, conar, cunningham, cushcraft, drake, ebooks, eddyston, eico, eimac, eldico, electro-voice, emc-partner, federal_telephone, ge, general_radio, gr, hallicra, henry, hickok, icom, jcpenny, jvc, kantronics, keithley, kenrad, kepco, lafayett, marantz, measurements, meissner, military, millen, national, philco, racal, rca, realistic, rme, sears, seco, sencore, sinclair, sony, sprague, sstran, swan, sylvania, tecsun, tek, tennelec, tentec, transcom, uniden, walter-ashe, wavetek, western-electric, weston, wrl, and yaesu.

Directories:

00readme:

Conversion material and schematic of mil receiver, R-45/ARR-7 based on SX-28. Compliments of Ray Colbert, W5XE and Kenneth Colbert, KB5MLY.

R45ARR-7AddSSB:

Adding SSB to the ARR-7 George Marshall W6BHR 554 Westborne Drive Los Angeles, Cal. 90048 I bought an ARR-7 from R. E. Goodheart after trying in vain to find anything with that complete coverage and overall quality at anywhere near the price. Although Goodheart had already removed and bypassed the reradiation suppressor, this article on adding SSB will be written for those who have an unmodified receiver. For those already possessing one of these versatile sets, or for those contemplating purchase, the ARR-7 is an extremely simple receiver in which to install a product detector. Proceeding directly to the heart of the matter, the following steps make it possible to modify the receiver in a few hours' time. First, remove and discard the 6AB7 which precedes the first of the two rf amplifiers. This tube was used only as a reradiation supressor so don't worry about losing gain or sensitivity in discarding it. The socket is utilized inthe modification and the tube is replaced by a 6SN7 Product Detector. The front-panel screws are loosened sufficiently to get an end wrench between the front panel and the chassis in order to remove the spst bfo switch. When the nut on the switch has been considerably loosened, the switch may he rotated about, so that with a gun-type iron, or other iron with a small tip, the connections may be removed from the terminals. Replace the old switch with a DPDT and reconnect the wires removed from the old switch in such fashion that they are switched ON in the bfo "ON" position. Use the uppermost terminals, the ones closest to the top of the receiver, for these connections, the single wire going to the center terminal and the pair of wires going to the other terminal. Returning to the vicinity of the 6AB7 socket, there is a terminal board immediately adjacent, on which are mounted ·79, C80, R54 and R55. Clip off, or unsolder these components so the terminal board can be re-used. Be careful when removing R-55, as this 47K resistor can be re-used as the plate load for the 6SN7. The B lead in the lower corner should also be carefully unsoldered, then the entire board can be removed for ease in installing the new components which consist of a .1 mf capacitor, a 10K ½ w resistor, and the reinstalled 47K resistor. The terminal board is modified as follows: Removethe ground connection which runs in the vertical plane and swing it around to the B lug. While the terminal board is out of the way the octal socket may be rewired for the 6SN7 as follows: Remove the antenna lead from pin 4 and the lead connected to pin 8. These two leads may now be directly connected by placing them on the unused lug of the terminal board when it is replaced. The jumper going from pin 3 to pin 5 is removed, carefully, fron pin 5 and connected to pin 6. If carefully removed, the ground lead connected to pins 1 and 2 can also be reused. A "soldering aid' tool is an asset for this sort of operation. A piece of spaghetti is slipped over this ground lead and it is then connected to pin 8 which takes care of the heater circuit. The other components are now connected to the socket, the 1OOK resistor from pin 1 to pin 8, the 1OOK resistor with a 100 pf capacitor across it, from pin 4 to pin 8 and a 680 ohm 1 w resistor from pin 6 to pin 8. (This is the only 1 w resistor; all others, are ½ w.) The terminal board can now be reinserted. When placing the .1 mf capacitor on the terminal board, leave enough lead on the B end and it can be used to connect directly to pin 5 on the octal socket. Remove the 3 screws from the bfo compartment and remove the cover. Inside you will notice a "gimmick," two wires twisted together; remove these and replace them with a 100 pf capacitor. Remove the lead going from the lug to the 6H6 for bfo injection. Remove the #6- 32 machine screw and place a ground lug un- der this screw and replace the screw. Replace the cover on the bfo. Prepare a 7" piece of small coax or shielded lead as follows. Strip one end so that about ½" of shield is exposed and about Ύ" of center conductor and its insulation. Strip off about Ό of this insulation exposing the center conductor. This end of the shield Will be connected to the ground lug installed on the bfo compartment and the Centex conductor connected to the lug which formerly went to 6H6. The othex end of the center conductor is connected to pin 1 of the tube socket. The 47K resistor from,the terminal board can now be connected to pin 2 of the socket. An 8½" piece of small coax is stripped in the same manner as the previous piece. With a hot iron, a place can be puddled and tinned with solder on the vertical wall of the bfo compartment nearest to pin 8 of the last if tube. The shield of the coax is grounded at this point and the exposed center conductor is connected through a 10 pf capacitor to pin 8 of the last if tube. The center conductor at the other end is connected to pin 4 of the 6SN7. Now, on the opposite side of the receiver there is a long terminal board. On it, near the rear of the receiver, is the audio coupling capacitor C77; the lead nearest you is removed and transferred to a blank lug which is toward the rear of the receiver. Now strip 2 26" pieces of small coax exposing the shield and center conductor at both ends. Strip another 26" piece so that the shield and center conductor is exposed only on one end. This end will be connected to the DPDT switch at the front panel. An three shielded leads can be snaked up through the harness along the right side of the receiver when looking at the bottom of the receiver, which will tend to keep things neat. The center conductor of the coax which is stripped on only one end is connected to pin 2 of the 6SN7. The center conductor at the other end is connected to the lug of the unused section of the DPDT bfo switch is closest to the center of the receiver. The center conductor of the next coax is connected to the center lug of the switch and the other end of the center conductor is connected to C77. The third coax center conductor is connected to the remaining lug on the switch, and thence connected to the point that C77 was removed from. The 3 shields at the point near the switch are wrapped with bare wire and soldered together. The other end of the two leads going to the audio can be tacked together in similar fashion. Where the lead which goes to the Product Detector, goes by the bfo compartment, about ½" of shield should be exposed and conneted to the same point as the lead which went to the last if (the solder puddle at the side wall of the bfo compartment). With all leads now installed on the 6SN7 socket, room can be found to connect the 10 mf decoupling capacitor to the ground lug of the adjacent tube. This completes the modification; plug in a 6SN7, hook up the power and start product detecting whenever the bfo is on. This modification does not affect ordinaTy CW reception, but makes it easy to tune and receive SSB signals. Either side band can be selected by adjustment of the bfo knob. It works like a charm ... W6BHR

r45arr-7addssb:

Adding SSB to the ARR-7 George Marshall W6BHR 554 Westborne Drive Los Angeles, Cal. 90048 I bought an ARR-7 from R. E. Goodheart after trying in vain to find anything with that complete coverage and overall quality at anywhere near the price. Although Goodheart had already removed and bypassed the reradiation suppressor, this article on adding SSB will be written for those who have an unmodified receiver. For those already possessing one of these versatile sets, or for those contemplating purchase, the ARR-7 is an extremely simple receiver in which to install a product detector. Proceeding directly to the heart of the matter, the following steps make it possible to modify the receiver in a few hours' time. First, remove and discard the 6AB7 which precedes the first of the two rf amplifiers. This tube was used only as a reradiation supressor so don't worry about losing gain or sensitivity in discarding it. The socket is utilized inthe modification and the tube is replaced by a 6SN7 Product Detector. The front-panel screws are loosened sufficiently to get an end wrench between the front panel and the chassis in order to remove the spst bfo switch. When the nut on the switch has been considerably loosened, the switch may he rotated about, so that with a gun-type iron, or other iron with a small tip, the connections may be removed from the terminals. Replace the old switch with a DPDT and reconnect the wires removed from the old switch in such fashion that they are switched ON in the bfo "ON" position. Use the uppermost terminals, the ones closest to the top of the receiver, for these connections, the single wire going to the center terminal and the pair of wires going to the other terminal. Returning to the vicinity of the 6AB7 socket, there is a terminal board immediately adjacent, on which are mounted ·79, C80, R54 and R55. Clip off, or unsolder these components so the terminal board can be re-used. Be careful when removing R-55, as this 47K resistor can be re-used as the plate load for the 6SN7. The B lead in the lower corner should also be carefully unsoldered, then the entire board can be removed for ease in installing the new components which consist of a .1 mf capacitor, a 10K ½ w resistor, and the reinstalled 47K resistor. The terminal board is modified as follows: Removethe ground connection which runs in the vertical plane and swing it around to the B lug. While the terminal board is out of the way the octal socket may be rewired for the 6SN7 as follows: Remove the antenna lead from pin 4 and the lead connected to pin 8. These two leads may now be directly connected by placing them on the unused lug of the terminal board when it is replaced. The jumper going from pin 3 to pin 5 is removed, carefully, fron pin 5 and connected to pin 6. If carefully removed, the ground lead connected to pins 1 and 2 can also be reused. A "soldering aid' tool is an asset for this sort of operation. A piece of spaghetti is slipped over this ground lead and it is then connected to pin 8 which takes care of the heater circuit. The other components are now connected to the socket, the 1OOK resistor from pin 1 to pin 8, the 1OOK resistor with a 100 pf capacitor across it, from pin 4 to pin 8 and a 680 ohm 1 w resistor from pin 6 to pin 8. (This is the only 1 w resistor; all others, are ½ w.) The terminal board can now be reinserted. When placing the .1 mf capacitor on the terminal board, leave enough lead on the B end and it can be used to connect directly to pin 5 on the octal socket. Remove the 3 screws from the bfo compartment and remove the cover. Inside you will notice a "gimmick," two wires twisted together; remove these and replace them with a 100 pf capacitor. Remove the lead going from the lug to the 6H6 for bfo injection. Remove the #6- 32 machine screw and place a ground lug un- der this screw and replace the screw. Replace the cover on the bfo. Prepare a 7" piece of small coax or shielded lead as follows. Strip one end so that about ½" of shield is exposed and about Ύ" of center conductor and its insulation. Strip off about Ό of this insulation exposing the center conductor. This end of the shield Will be connected to the ground lug installed on the bfo compartment and the Centex conductor connected to the lug which formerly went to 6H6. The othex end of the center conductor is connected to pin 1 of the tube socket. The 47K resistor from,the terminal board can now be connected to pin 2 of the socket. An 8½" piece of small coax is stripped in the same manner as the previous piece. With a hot iron, a place can be puddled and tinned with solder on the vertical wall of the bfo compartment nearest to pin 8 of the last if tube. The shield of the coax is grounded at this point and the exposed center conductor is connected through a 10 pf capacitor to pin 8 of the last if tube. The center conductor at the other end is connected to pin 4 of the 6SN7. Now, on the opposite side of the receiver there is a long terminal board. On it, near the rear of the receiver, is the audio coupling capacitor C77; the lead nearest you is removed and transferred to a blank lug which is toward the rear of the receiver. Now strip 2 26" pieces of small coax exposing the shield and center conductor at both ends. Strip another 26" piece so that the shield and center conductor is exposed only on one end. This end will be connected to the DPDT switch at the front panel. An three shielded leads can be snaked up through the harness along the right side of the receiver when looking at the bottom of the receiver, which will tend to keep things neat. The center conductor of the coax which is stripped on only one end is connected to pin 2 of the 6SN7. The center conductor at the other end is connected to the lug of the unused section of the DPDT bfo switch is closest to the center of the receiver. The center conductor of the next coax is connected to the center lug of the switch and the other end of the center conductor is connected to C77. The third coax center conductor is connected to the remaining lug on the switch, and thence connected to the point that C77 was removed from. The 3 shields at the point near the switch are wrapped with bare wire and soldered together. The other end of the two leads going to the audio can be tacked together in similar fashion. Where the lead which goes to the Product Detector, goes by the bfo compartment, about ½" of shield should be exposed and conneted to the same point as the lead which went to the last if (the solder puddle at the side wall of the bfo compartment). With all leads now installed on the 6SN7 socket, room can be found to connect the 10 mf decoupling capacitor to the ground lug of the adjacent tube. This completes the modification; plug in a 6SN7, hook up the power and start product detecting whenever the bfo is on. This modification does not affect ordinaTy CW reception, but makes it easy to tune and receive SSB signals. Either side band can be selected by adjustment of the bfo knob. It works like a charm ... W6BHR

R45ARR-7mods:

R-45/ ARR-7 Receiver Modifications James M. Stueber W5UOZ-AF5UOZ 8410 Flower Place N.E. Albuquerque, N. M. The R-45/ARR-7 receiver is a continuous tuning type covering the range of .55 mc thru 42 mc. It is a single conversion superhetrodyne circuit, with two tuned rf stages and one untuned preselector rf stage. The design is a modification of the well known Hallicrafters SX-28 receiver. The particular modified receiver was built under a Signal Corps contract by the Belmont Radio Corp. Inclusion of the described changes will provide the user with a good communications receiver, overcoming the major disadvantage in the original design, which is the lack of bandspread tuning. A schematic of the receiver and a coil layout for alignment purposes is included for those who may require them. Appreciation is extended to Mr. Amos Peters, AF5LHX, for supplying the receiver through the MARS Central Technical Net, thereby making these modifications possible. The changes described consist of the following: 1. Addition of bandspread tuning and dial 2. Addition of necessary wiring to provide ac power supply operation 3. Addition of Send-Rev. Switch 4. Improvement of "S" meter circuit 5. Audio amplifier modification for speaker connection 6. Low impedance antenna input stage Bandspread Tuning and Modification for ac Power 1. Remove the screws holding the cover plate which houses the tuning dial motor reversing switch and stop mechanism. Discard. 2. Cut the wires from the motor reversing switch SW3 and remove the switch. 3. Remove the stop mechanism from the main tuning dial shaft and discard. 4. Remove all the knobs from the receiver and the screws from the power connector so the front panel may be taken off. 5. Remove the main tuning dial by loosening the allen-head screws. 6. Remove the cover from the cast aluminum housing containing the 28V dc motor and associated parts. 7. Remove the filter, motor and misc. parts from inside the box. 8. Remove the fiber gear from the vertical shaft. This may be sealed with paint and may be difficult to loosen, but with the proper size allen wrench and solvent to loosen the paint, it will come loose. 9. Remove the potentiometer R41 and bracket, located on the top rear of the chassis. Cut the wire leads free near the potentiometer terminals and leave them in position. 10. Remove the wires from the POWER switch, tie together, solder and insulate. 11. Remove the white wire with blue and orange tracer from the MOTOR switch. 12. Remove the ground connections from pins A and C of receptacle SO-1. 13. Attach the white wire, with blue and orange tracer, which was removed from the MOTOR switch, to one lug of the POWER switch. 14. Attach the other end of the wire which was attached to the motor, to pin C of SO-1 connector. 15. Cut the white wire with green tracer from the MOTOR switch and attach to the other lug of the POWER switch. Pins C and D of SO-1 now become the ac switch-wires to turn ae power off and on. The bandspread tuning knob will project out of the top of the case, since there is no front panel space available. 16. A three-eighths inch hole is drilled in the top of the cast aluminum motor housing located 11/16 inch from the front of the case, and Ό inch from the left. A shaft bushing is installed in this hole to accommodate a length of Ό inch diameter shaft and solid shaft coupling. The bandspread tuning will be engaged by throwing the MOTOR switch to ON, which engages the electric clutch in the tuning mechanism. When fast tuning is desired, the MOTOR switch is thrown to OFF and tuning is accomplished with the TUNING knob. Parts are now installed to provide de voltage to energize the clutch. 17. Mount a 6.3 volt 1.2 amp. filament transformer under the chassis on the side lip near the SO-1 connector. Refer to Fig. 1 for the schematic of this portion of the modification. 18. Connect one of the 6.3 volt leads of the transformer to pin 7 of 6SA7 tube V4. 19. The center tap connection of this winding is not used, so cut the lead off close to the transformer winding. 20. Remove the wire with blue tracer from the MOTOR switch. 21. Connect the other 6.3 volt lead to one con- tact on the MOTOR switch. 22. Connect the other switch contact to a con- ven,ient ground. 23. The 500 ohm 5 watt resistor, the 1N93 diode, and 10 mfd capacitor are conveniently located near the transformer on a three lug terminal strip and wired as shown in Fig. 1. 24. Connect the wire with blue tracer, which was removed from the MOTOR switch, to the junction of the 1N93 diode and the 10 mfd capacitor shown in Fig. 1. Addition of SEND-RCV Switch 1. Drill two holes in the front panel which will accommodate a SEND-RCV switch and a pin jack (RCA Phono jack) for a keying relay connection. Due to the close spacings and limited panel space available, care must be exercised in location of the two holes. A ½ inch hole for the SEND-RCV switch is located 5½ inches from the left and 1 13/16 up from the bottom. A three-eighths inch hole for the pin, jack is drilled 6 inches from the left and 2 7/16 inches up from the bottom of the front panel. Refer to Fig. 2 for the schematic of the circuit. 2. Estimate the length of wire needed to go from pin A and B of SO-1 to the new SEND-RCV switch, a SPST toggle switch on the front panel, and install these leads. Do not solder these leads at the toggle switch at this time but solder at pin A and B of SO-1. 3. Estimate two lengths of wire to run from the toggle switch to the pin jack. The toggle switch wire from pin A of SO-1 goes to the insulated lug of the pin jack and the other wire from the toggle switch to the ground lug of the pin jack. Solder all these leads at this time. 4. The main tuning dial, front panel, and knobs may now be reassembled. Improvement of "S" Meter Circuit It was found that the maximum deflection that could be had from the local broadcast signals was S-6 with the original circuitry. The following changes will improve the circuit. Refer to Fig. 3 for the revised circuit. 1. Replace the 6SK7 tube V5 with a 6SD7 tube. 2. Change the 100 ohm resistor R22 tb 1000 ohms. 3. Add a 1000 ohm resistor in parallel with the 330 ohm resistor at he cathode of V5. Audio Amplifier Modification Refer to Fig. 4 for the revised circuit. 1. Remove the 68k resistor R39 located on the terminal board on the back chassis lip. 2. Tie a jumper wire across the two terminals where R39 resistor was removed and solder. 3. Remove the 7500 ohm 10 watt resistor R40 located in a cluster of four upright resistors under the chassis near the rear. 4. Connect the two white wires with red tracers together after removing them from R40, insulate and solder them. 5. Install a 5000 ohm to 8 ohm output transformer in the location on top of the chassis near the rear where the R41 potentiometer and bracket were removed. 6. Remove the white wire with blue tracer attached to pin 3 of 6V6 tube V9. This wire leads to a .5 mfd capacitor C52 which is a metal can type and is the bottom unit of two stacked ones near the cluster of upright mounted 10 watt resistors. This capacitor may be removed or left in, as desired, and white wire with blue tracer may be removed from the harness or clipped short and left in. 7. Install a wire from the other terminal of C52 to a lead of the 8 ohm secondary of the output transformer. (There is already a shielded wire attached to this terminal of C52, leave it there.) 8. Tie the other lead of the 8 ohm transformer secondary to any convenient ground. The white wire with black tracer which attached to the potentiometer R41 may he used for this ground. 9. Connect one wire of the output transformer primary to pin 3 of 6VO tube V9. Do not solder. 10. Connect the other primary wire to pin 4 of OVO tube V9. Do not solder. 11. Remove the 100k resistor R47 connected from pin 3 of 6V6 tube V9 to a terminal board on the rear chassis apron. Removal of this negative feedback resistor will result in greater output and better communications quality. 12. Install a .02 mfd 600 volt capacitor from pin 3 to pin 4 of 6V6 tube V9 to reduce high frequency response. Solder the connections. Either headphones or a speaker may be connected to the PHONES jack. Low Impedance Antenna Input Stage Refer to Fig. 5 for the revised schematic. 1. Remove the wire lead from pin 5 to pin 3 of 6AB7 tube V12. 2. Connect a wire from pin 3 to pin I of this tube socket and solder. 3. Remove the .0082 mfd capacitor C79 from the terminal board on the underside of the chassis near the tube socket of V12. 4. Disconnect the center wire of the shielded antenna wire lead where it terminates at the terminal board on top of the chassis near the 6AB7 tube V12. 5. Ground the terminal from which this wire was removed. 6. Connect one end of a .0082 mfd capacitor to the free end of the wire removed in step 4 and add on a piece of wire to the other end of the capacitor, long enough to go through the chassis grommet. Connect it to pin 5 of the 6AB7 tube V12. A typical power supply is shown in the schematic of Fig. 6. No attempt is made to design an exact supply for the receiver in this article, since most users have power supplies capable of supplying adequate power to the receiver. A white wire with blue and black tracer will be left over from the modifications. It may be cut close and left in the harness under the chassis. A slot is cut in the cover to allow it to be slipped over the bandspread tuning knob. This shaft may be cut short enough to allow a knob to fit flush with the case cover. A dummy knob is installed on the shaft on the front panel from which the stop mechanism was removed. A bandspread dial is attached with cement to a Ύ inch diameter knob and installed on the tuning shaft. This dial is reproduced in Fig. 7 as a guide only because each receiver will vary slightly in calibration and the,dial will have to be tailored to each case. A suitable pointer for the dial is made from a short length of solid #20 wire which is attached under the screwhead of the nameplate. . . . W5UOZ Parts List 1-Shaft bushing for Ό inch shaft 1-Ό inch dia. shaft approx. 4 inches long 1-shaft coupling for 1/4 inch shaft 1-2 inch dia. bandspread tuning knob 1-SPST toggle switch (SEND-RCV switch) 1-Pin jack (RCA phono jack) 1-Ύ inch dia. tuning knob (mount bandsproad tuning dial to this knob) 1-6.3 volt 1.2 amp filament transformer 1-1N93 diode 1-10 mfd 150 volt elect. capacitor 1-500 ohm 5 watt resistor 1-8 Ing terminal strip 1-6SD7 tube 2-1000 ohm ½ watt resistor 1-5000 ohm to 8 ohm output transformer, 5 watt 1-.02 mfd 600 volt capacitor 1-1 Mh rf choke

r45arr-7mods:

R-45/ ARR-7 Receiver Modifications James M. Stueber W5UOZ-AF5UOZ 8410 Flower Place N.E. Albuquerque, N. M. The R-45/ARR-7 receiver is a continuous tuning type covering the range of .55 mc thru 42 mc. It is a single conversion superhetrodyne circuit, with two tuned rf stages and one untuned preselector rf stage. The design is a modification of the well known Hallicrafters SX-28 receiver. The particular modified receiver was built under a Signal Corps contract by the Belmont Radio Corp. Inclusion of the described changes will provide the user with a good communications receiver, overcoming the major disadvantage in the original design, which is the lack of bandspread tuning. A schematic of the receiver and a coil layout for alignment purposes is included for those who may require them. Appreciation is extended to Mr. Amos Peters, AF5LHX, for supplying the receiver through the MARS Central Technical Net, thereby making these modifications possible. The changes described consist of the following: 1. Addition of bandspread tuning and dial 2. Addition of necessary wiring to provide ac power supply operation 3. Addition of Send-Rev. Switch 4. Improvement of "S" meter circuit 5. Audio amplifier modification for speaker connection 6. Low impedance antenna input stage Bandspread Tuning and Modification for ac Power 1. Remove the screws holding the cover plate which houses the tuning dial motor reversing switch and stop mechanism. Discard. 2. Cut the wires from the motor reversing switch SW3 and remove the switch. 3. Remove the stop mechanism from the main tuning dial shaft and discard. 4. Remove all the knobs from the receiver and the screws from the power connector so the front panel may be taken off. 5. Remove the main tuning dial by loosening the allen-head screws. 6. Remove the cover from the cast aluminum housing containing the 28V dc motor and associated parts. 7. Remove the filter, motor and misc. parts from inside the box. 8. Remove the fiber gear from the vertical shaft. This may be sealed with paint and may be difficult to loosen, but with the proper size allen wrench and solvent to loosen the paint, it will come loose. 9. Remove the potentiometer R41 and bracket, located on the top rear of the chassis. Cut the wire leads free near the potentiometer terminals and leave them in position. 10. Remove the wires from the POWER switch, tie together, solder and insulate. 11. Remove the white wire with blue and orange tracer from the MOTOR switch. 12. Remove the ground connections from pins A and C of receptacle SO-1. 13. Attach the white wire, with blue and orange tracer, which was removed from the MOTOR switch, to one lug of the POWER switch. 14. Attach the other end of the wire which was attached to the motor, to pin C of SO-1 connector. 15. Cut the white wire with green tracer from the MOTOR switch and attach to the other lug of the POWER switch. Pins C and D of SO-1 now become the ac switch-wires to turn ae power off and on. The bandspread tuning knob will project out of the top of the case, since there is no front panel space available. 16. A three-eighths inch hole is drilled in the top of the cast aluminum motor housing located 11/16 inch from the front of the case, and Ό inch from the left. A shaft bushing is installed in this hole to accommodate a length of Ό inch diameter shaft and solid shaft coupling. The bandspread tuning will be engaged by throwing the MOTOR switch to ON, which engages the electric clutch in the tuning mechanism. When fast tuning is desired, the MOTOR switch is thrown to OFF and tuning is accomplished with the TUNING knob. Parts are now installed to provide de voltage to energize the clutch. 17. Mount a 6.3 volt 1.2 amp. filament transformer under the chassis on the side lip near the SO-1 connector. Refer to Fig. 1 for the schematic of this portion of the modification. 18. Connect one of the 6.3 volt leads of the transformer to pin 7 of 6SA7 tube V4. 19. The center tap connection of this winding is not used, so cut the lead off close to the transformer winding. 20. Remove the wire with blue tracer from the MOTOR switch. 21. Connect the other 6.3 volt lead to one con- tact on the MOTOR switch. 22. Connect the other switch contact to a con- ven,ient ground. 23. The 500 ohm 5 watt resistor, the 1N93 diode, and 10 mfd capacitor are conveniently located near the transformer on a three lug terminal strip and wired as shown in Fig. 1. 24. Connect the wire with blue tracer, which was removed from the MOTOR switch, to the junction of the 1N93 diode and the 10 mfd capacitor shown in Fig. 1. Addition of SEND-RCV Switch 1. Drill two holes in the front panel which will accommodate a SEND-RCV switch and a pin jack (RCA Phono jack) for a keying relay connection. Due to the close spacings and limited panel space available, care must be exercised in location of the two holes. A ½ inch hole for the SEND-RCV switch is located 5½ inches from the left and 1 13/16 up from the bottom. A three-eighths inch hole for the pin, jack is drilled 6 inches from the left and 2 7/16 inches up from the bottom of the front panel. Refer to Fig. 2 for the schematic of the circuit. 2. Estimate the length of wire needed to go from pin A and B of SO-1 to the new SEND-RCV switch, a SPST toggle switch on the front panel, and install these leads. Do not solder these leads at the toggle switch at this time but solder at pin A and B of SO-1. 3. Estimate two lengths of wire to run from the toggle switch to the pin jack. The toggle switch wire from pin A of SO-1 goes to the insulated lug of the pin jack and the other wire from the toggle switch to the ground lug of the pin jack. Solder all these leads at this time. 4. The main tuning dial, front panel, and knobs may now be reassembled. Improvement of "S" Meter Circuit It was found that the maximum deflection that could be had from the local broadcast signals was S-6 with the original circuitry. The following changes will improve the circuit. Refer to Fig. 3 for the revised circuit. 1. Replace the 6SK7 tube V5 with a 6SD7 tube. 2. Change the 100 ohm resistor R22 tb 1000 ohms. 3. Add a 1000 ohm resistor in parallel with the 330 ohm resistor at he cathode of V5. Audio Amplifier Modification Refer to Fig. 4 for the revised circuit. 1. Remove the 68k resistor R39 located on the terminal board on the back chassis lip. 2. Tie a jumper wire across the two terminals where R39 resistor was removed and solder. 3. Remove the 7500 ohm 10 watt resistor R40 located in a cluster of four upright resistors under the chassis near the rear. 4. Connect the two white wires with red tracers together after removing them from R40, insulate and solder them. 5. Install a 5000 ohm to 8 ohm output transformer in the location on top of the chassis near the rear where the R41 potentiometer and bracket were removed. 6. Remove the white wire with blue tracer attached to pin 3 of 6V6 tube V9. This wire leads to a .5 mfd capacitor C52 which is a metal can type and is the bottom unit of two stacked ones near the cluster of upright mounted 10 watt resistors. This capacitor may be removed or left in, as desired, and white wire with blue tracer may be removed from the harness or clipped short and left in. 7. Install a wire from the other terminal of C52 to a lead of the 8 ohm secondary of the output transformer. (There is already a shielded wire attached to this terminal of C52, leave it there.) 8. Tie the other lead of the 8 ohm transformer secondary to any convenient ground. The white wire with black tracer which attached to the potentiometer R41 may he used for this ground. 9. Connect one wire of the output transformer primary to pin 3 of 6VO tube V9. Do not solder. 10. Connect the other primary wire to pin 4 of OVO tube V9. Do not solder. 11. Remove the 100k resistor R47 connected from pin 3 of 6V6 tube V9 to a terminal board on the rear chassis apron. Removal of this negative feedback resistor will result in greater output and better communications quality. 12. Install a .02 mfd 600 volt capacitor from pin 3 to pin 4 of 6V6 tube V9 to reduce high frequency response. Solder the connections. Either headphones or a speaker may be connected to the PHONES jack. Low Impedance Antenna Input Stage Refer to Fig. 5 for the revised schematic. 1. Remove the wire lead from pin 5 to pin 3 of 6AB7 tube V12. 2. Connect a wire from pin 3 to pin I of this tube socket and solder. 3. Remove the .0082 mfd capacitor C79 from the terminal board on the underside of the chassis near the tube socket of V12. 4. Disconnect the center wire of the shielded antenna wire lead where it terminates at the terminal board on top of the chassis near the 6AB7 tube V12. 5. Ground the terminal from which this wire was removed. 6. Connect one end of a .0082 mfd capacitor to the free end of the wire removed in step 4 and add on a piece of wire to the other end of the capacitor, long enough to go through the chassis grommet. Connect it to pin 5 of the 6AB7 tube V12. A typical power supply is shown in the schematic of Fig. 6. No attempt is made to design an exact supply for the receiver in this article, since most users have power supplies capable of supplying adequate power to the receiver. A white wire with blue and black tracer will be left over from the modifications. It may be cut close and left in the harness under the chassis. A slot is cut in the cover to allow it to be slipped over the bandspread tuning knob. This shaft may be cut short enough to allow a knob to fit flush with the case cover. A dummy knob is installed on the shaft on the front panel from which the stop mechanism was removed. A bandspread dial is attached with cement to a Ύ inch diameter knob and installed on the tuning shaft. This dial is reproduced in Fig. 7 as a guide only because each receiver will vary slightly in calibration and the,dial will have to be tailored to each case. A suitable pointer for the dial is made from a short length of solid #20 wire which is attached under the screwhead of the nameplate. . . . W5UOZ Parts List 1-Shaft bushing for Ό inch shaft 1-Ό inch dia. shaft approx. 4 inches long 1-shaft coupling for 1/4 inch shaft 1-2 inch dia. bandspread tuning knob 1-SPST toggle switch (SEND-RCV switch) 1-Pin jack (RCA phono jack) 1-Ύ inch dia. tuning knob (mount bandsproad tuning dial to this knob) 1-6.3 volt 1.2 amp filament transformer 1-1N93 diode 1-10 mfd 150 volt elect. capacitor 1-500 ohm 5 watt resistor 1-8 Ing terminal strip 1-6SD7 tube 2-1000 ohm ½ watt resistor 1-5000 ohm to 8 ohm output transformer, 5 watt 1-.02 mfd 600 volt capacitor 1-1 Mh rf choke

Files:

Enable Javascript to download files

addssb.djvu

(7.7 KB)

R45-ARR-7 Modifications 73 Mag 12_Dec_1962.pdf

(1.6 MB)

r45arr7mods.djvu

(89 KB)